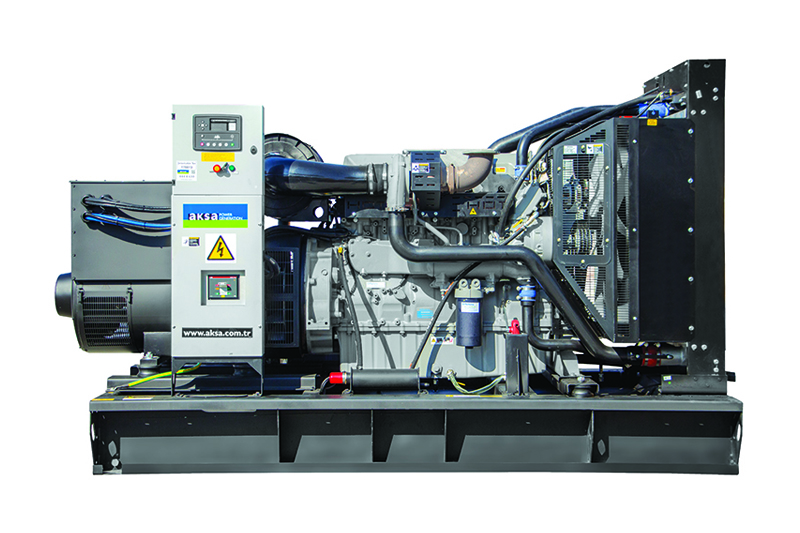

AP 660

Product: PERKINS

Alternator: ECO 40-2L/4 C

Regelsystemen: DSE 7320

Over Product

Algemene kenmerken

3 Fasen, 50 Hz, PF 0.8

Motorkenmerken

Dynamo specificaties

Grootte en gewicht

Standaardfuncties

Aksa power generation system, providing optimum performance, and reliability, for stationary standby, prime power, and continuous duty applications. All generator sets are factory build, and production tested.

Certificaten

TS ISO 8528

CE

SZUTEST

2000/14/EC

| Modelnaam |

AP 660 |

||

|---|---|---|---|

| Frequentie (HZ) |

50 |

||

| Brandstoftype |

Diesel |

||

| Motormerk en -model |

PERKINS - 2806A-E18TAG1A |

||

| Alternatormerk en -model |

Mecc Alte - ECO 40-2L/4 C |

||

| Configuratiescherm Model |

DSE 7320 |

||

| Cabine | MS 86-AP660 |

| Spanning | Stand-by vermogen (ESP) | Prime Power (PRP) | Standby Amper | ||

|---|---|---|---|---|---|

| kVA | kW | kVA | kW | ||

| 400/231 | 660 | 528.00 | 600 | 480.00 | 952.66 |

Stand-by vermogen (ESP) : Het wordt gebruikt om te voldoen aan de variabele elektrische belastingvereiste in geval van uitval van de betrouwbare netvoeding. ESP voldoet aan ISO 8528-1 Overbelasting is niet toegestaan.

Prime Power (PRP) : Wordt gedefinieerd als het continue bedrijfsvermogen onder variabele belasting. PRP voldoet aan ISO 8528-1 10% overbelasting kan elke 12 uur worden gedaan.

Prime Power (PRP) : Wordt gedefinieerd als het continue bedrijfsvermogen onder variabele belasting. PRP voldoet aan ISO 8528-1 10% overbelasting kan elke 12 uur worden gedaan.

| Motor |

PERKINS |

||

|---|---|---|---|

| Motor model | 2806A-E18TAG1A | ||

| Aantal Cilinders En Gebouw | 6 cylinders - in line | ||

| Boor En Slag | mm | 145 X 183 | |

| Totale Verplaatsing | L | 18,13 | |

| Aspiratie | Turbo Charged and Charge Air Cooled | ||

| Compressieverhouding | 14,5:1 | ||

| Nominale snelheid | d/dk | 1500 | |

| Olie capaciteit | L | 62 | |

| Stand-by vermogen (kW/HP) | 593/795 | ||

| Prime Power (kW/HP) | 540/724 | ||

| Blokverwarmingshoeveelheid | |||

| 1 | |||

| Blokkeer verwarmingsvermogen (Watt) | 3000 | ||

| Brandstoftype | |||

| Diesel | |||

| Type brandstofpomp | |||

| MEUI | |||

| Governor-systeem | |||

| ECM | |||

| Bedrijfsspanning (Vdc) | |||

| 24 Vdc | |||

| Batterij en capaciteit (aantal / Ah) | 2x143 | ||

| Laaddynamo (A) | |||

| 45 | |||

| Koelmethode | |||

| Water Cooled | |||

| Koelventilatorluchtstroom (m³ / min) | 650 | ||

| Koelvloeistofcapaciteit (alleen motor / met radiator) (lt) | /61 | ||

| Luchtfilter | |||

| Dry Type | |||

| Brandstofverbruik bij eerste 100% belasting (lt / uur) | 123 | ||

| Brandstofverbruik primair 75% belasting (lt / uur) | 90 | ||

| Brandstofverbruik bij eerste 50% belasting (lt / uur) | 61 | ||

| Fabrikant | Mecc Alte | |

|---|---|---|

| Alternatormerk en -model | ECO 40-2L/4 C | |

| Frequentie (HZ) | Hz | 50 |

| Kracht (kVA) | kVA | 625 |

| Ontwerp | 4 Pole, Brushless | |

| Spanning | V | 400 |

| Fase | 3 | |

| Automatische spanningsregelaar | DER1 | |

| Voltage regulatie | (+/-) | 0.5 |

| Isolatiesysteem | H | |

| Bescherming | IP23 | |

| Nominale vermogensfactor | 0.8 | |

| Gewicht dynamo (Kg) | 1456 | |

| Koellucht (m³/min) | m3 | 54 |

| Open Type | Droog gewicht (kg.) (kg.) |

Lengte (mm.) |

Breedte (mm.) |

Hoogte (mm.) |

Inhoud brandstoftank (lt.) (Lt.) |

|---|---|---|---|---|---|

|

4250 | 3450 | 1800 | 2171 | 1150 |

| Cabin Group | Droog gewicht (kg.) (kg.) |

Lengte (mm.) |

Breedte (mm.) |

Hoogte (mm.) |

Inhoud brandstoftank (lt.) (Lt.) |

MS 86-AP660

|

5670 | 5383 | 1800 | 2503 | 1150 |

- Water cooled, Diesel engine

- Radiator with mechanical fan

- Protective grille for rotating and hot parts

- Electric starter and charge alternator

- Starting battery (with lead acid) including rack and cables

- Engine coolant heater

- Base frame design incorporates an integral fuel tank and anti-vibration isolators

- Flexible fuel connection hoses

- Single bearing, class H alternator

- Industrial exhaust silencer and steel bellows supplied separately(for open sets)

- Static battery charger

- Manual for application and installation

Generator hardware-opties

- Radiator with mechanical fan

- Protective grille for rotating and hot parts

- Electric starter and charge alternator

- Starting battery (with lead acid) including rack and cables

- Engine coolant heater

- Base frame design incorporates an integral fuel tank and anti-vibration isolators

- Flexible fuel connection hoses

- Single bearing, class H alternator

- Industrial exhaust silencer and steel bellows supplied separately(for open sets)

- Static battery charger

- Manual for application and installation

ENGINE

- Fuel-Water Seperator Filter

- Oil heater

- Anti-Condensation Heater

- Over sized alternatör

- Main line circuit breaker

- Remote annunciator panel

- Remote relay output

- Alarm output relays

- Remote communication with modem

- Earth fault, single set

- Charge Ammeter

- Three or four pole contactor

- Three or four pole motor operated circuit breaker

- Main Fuel Tank

- Automatic or manual fuel filling system

- Manual oil drain pump

- Electrical oil drain pump

- Residential silencer

- Enclosure: weater protective or sound attenuated

- Duct adapter ( on radiator)

- Inlet and outlet motorised louvers

- Inlet and outlet acoustic baffles

- Trailer

- Tool kit for maintenance

- Supplied with oil and coolant - 30 °C

- Battery isolating swich

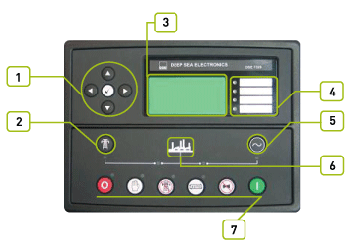

Regelsystemen: DSE 7320

1. Menu navigation buttons

2. Close mains button

3. Main Status and instrumentation display

4. Alarm LED's

5. Close generator button

6. Status LED's

7. Operation selecting buttons

2. Close mains button

3. Main Status and instrumentation display

4. Alarm LED's

5. Close generator button

6. Status LED's

7. Operation selecting buttons

Apparaten

DSE, model 7320 Auto Mains Failure control module Static battery charger Emergency stop push button and fuses for control circuits

Structuur en verf

Comonents installed in sheet steel enclosure.

Phosphate chemical, pre-coating of steel provides corrosion resistant surface

Polyester composite powder topcoat forms high gloss and extremely durable finish

Lockable hinged panel door provides for easy component access

Montage

Phosphate chemical, pre-coating of steel provides corrosion resistant surface

Polyester composite powder topcoat forms high gloss and extremely durable finish

Lockable hinged panel door provides for easy component access

Control panel is mounted generating set baseframe on robust steel stand or power module. Located at side of generating set with properly panel visibility.

Generator regeleenheid

The DSE 7320 conrol module is a standard addition to our generator sets from 220 kVA upwards and it has been designed to start and stop diesel andgas generating sets that include electronic and non electronic engines.

The DSE 7320 includes the additional capability of being able to monitor a mains (utility) supply and is therefore suitable for controlling a standby generating set in conjunction with an automatic transfer switch.

The DSE7320 also indicates operational status and fault conditions, automatically shutting down the generating set and indicating faults by means of its LCD display on the front panel.

Standaardfuncties

Microprocessor controlled

- 132 x 64 pixel LCD display makes information easy to read

- Front panel programming and also via PC software

- Soft touch membrane keypad and five key menu navigation

- Remote communications via RS232, RS485 and ethernet.

- Event logging (50) showing date and time

- Multiple date and time engine exercise mode and maintenance scheduler

- Engine block heater control.

- Controls; stop, manuel, auto, test, start, mute lamb test/transfer to generator, transfer to mains, menu navigation.

Elektronische acculader

The DSE 7320 includes the additional capability of being able to monitor a mains (utility) supply and is therefore suitable for controlling a standby generating set in conjunction with an automatic transfer switch.

The DSE7320 also indicates operational status and fault conditions, automatically shutting down the generating set and indicating faults by means of its LCD display on the front panel.

Standaardfuncties

Microprocessor controlled

- 132 x 64 pixel LCD display makes information easy to read

- Front panel programming and also via PC software

- Soft touch membrane keypad and five key menu navigation

- Remote communications via RS232, RS485 and ethernet.

- Event logging (50) showing date and time

- Multiple date and time engine exercise mode and maintenance scheduler

- Engine block heater control.

- Controls; stop, manuel, auto, test, start, mute lamb test/transfer to generator, transfer to mains, menu navigation.

Meetindicatoren

ENGINE

Engine speed

Oil pressure

Coolant temperature

Run time Battery volts

Engine maintenance due

GENERATOR

Voltage (L-L, L-N)

Current (L1-L2-L3)

Frequency

Earth current

kW

Pf

kVAr

kWh, kVAh, kVArh

Phase sequence

MAINS

Voltage (L-L, L-N)

Frequency

ENGINE

Engine speed

Oil pressure

Coolant temperature

Run time Battery volts

Engine maintenance due

GENERATOR

Voltage (L-L, L-N)

Current (L1-L2-L3)

Frequency

Earth current

kW

Pf

kVAr

kWh, kVAh, kVArh

Phase sequence

MAINS

Voltage (L-L, L-N)

Frequency

Beveiligingscircuits

WARNING

Charge failure

Battery under voltage

Fail to stop

Low fuel level (opt.)

kW over load

Negative phase sequence

Loss of speed signal

PRE-ALARMS

Low oil pressure

High engine temperature

Low engine temperature

Over /Under speed

Under/over generator frequency

Under/over generator voltage

ECU warning

SHUT DOWNS

Fail to start

Emergency stop

Low oil pressure

High engine temperature

Low coolant level

Over /Under speed

Under/over generator frequency

Under/over generator voltage

Oil pressure sensor open

Phase rotation

ELECTRICAL TRIP

Earth fault

kW over load

Generator over current

Negative phase sequence

WARNING

Charge failure

Battery under voltage

Fail to stop

Low fuel level (opt.)

kW over load

Negative phase sequence

Loss of speed signal

PRE-ALARMS

Low oil pressure

High engine temperature

Low engine temperature

Over /Under speed

Under/over generator frequency

Under/over generator voltage

ECU warning

SHUT DOWNS

Fail to start

Emergency stop

Low oil pressure

High engine temperature

Low coolant level

Over /Under speed

Under/over generator frequency

Under/over generator voltage

Oil pressure sensor open

Phase rotation

ELECTRICAL TRIP

Earth fault

kW over load

Generator over current

Negative phase sequence

Optie Kenmerken

High oil temperature shut down

Low fuel level shut down

Low fuel level alarm

High fuel level alarm

EXPANSION MODULES

Editional LED module (2548)

Expension relay module (2157)

Expansion input module (2130)

High oil temperature shut down

Low fuel level shut down

Low fuel level alarm

High fuel level alarm

EXPANSION MODULES

Editional LED module (2548)

Expension relay module (2157)

Expansion input module (2130)

Standaarden

Elecrical Safety / EMC compatibility

BS EN 60950 Electrical business equipment

BS EN 61000-6-2 EMC immunity standard

BS EN 61000-6-4 EMC emission standard

Elecrical Safety / EMC compatibility

BS EN 60950 Electrical business equipment

BS EN 61000-6-2 EMC immunity standard

BS EN 61000-6-4 EMC emission standard

Battery charger is manufactured with switching-mode and SMD technology and it has high efficincy.

Battery charger models' output V-I characteristic is very close to square

2405 has fully output shot circuit protection and ıt can be used as a current source.

2405 charger has high efficiency, long life, low failure rate, light weight and low heat radiated in accordance with linear alternatives.

The charger is fitted with a protection diode across the output.

Charge fail output is available.

Connect charge fail relay coil between positive output and CF output.

Input: 196-264V.

Output: 27,6V 5A or 13,8V 5A.

Battery charger models' output V-I characteristic is very close to square

2405 has fully output shot circuit protection and ıt can be used as a current source.

2405 charger has high efficiency, long life, low failure rate, light weight and low heat radiated in accordance with linear alternatives.

The charger is fitted with a protection diode across the output.

Charge fail output is available.

Connect charge fail relay coil between positive output and CF output.

Input: 196-264V.

Output: 27,6V 5A or 13,8V 5A.

Cabine: MS 86-AP660

Standaardfuncties

| Kastserie Model | MS 86-AP660 | |

|---|---|---|

| Breedte | mm. | 1800 |

| Lengte | mm. | 5383 |

| Hoogte | mm. | 2503 |

| Inhoud brandstoftank (lt.) | Lt. | 1150 |